Description

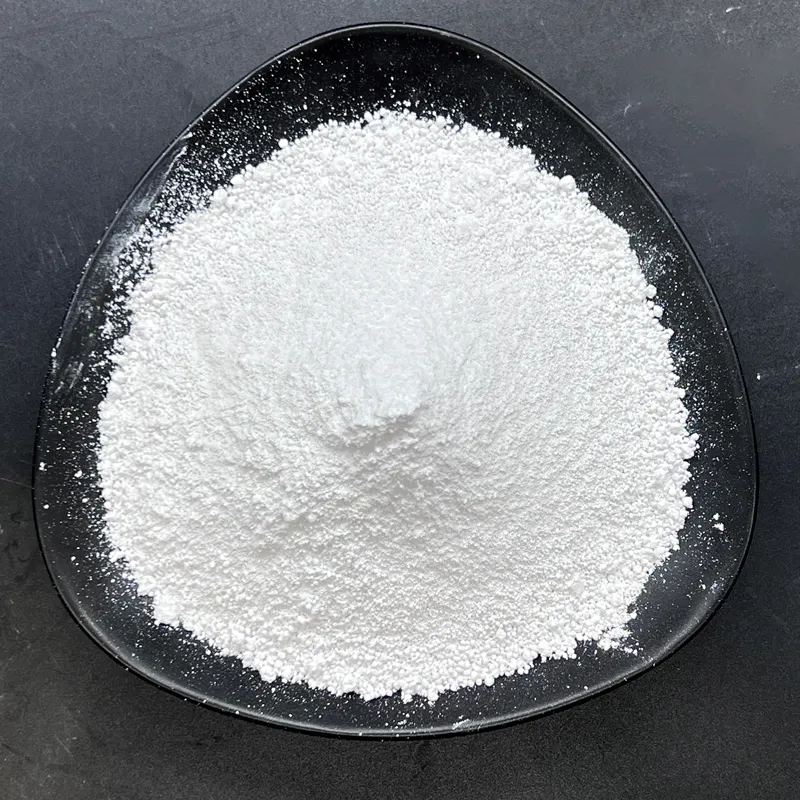

Activated alumina is made from aluminum hydroxide by dehydroxylation, resulting in a highly porous material; The surface area of this material can exceed 200 m2/g. Activated alumina has the characteristics of high strength, low wear, no softening in water, no expansion, no powder, no cracking. The application categories are desiccant and defluorination and arsenic removal agent, hydrogen peroxide special catalyst, catalyst carrier, TBC special adsorbent, dechlorination agent, air purification food preservation.