For A Better World

Abrasive Materials Manufacturer With 26 Years Experience

Who We Are

We are a factory that produces high-quality abrasive grains with advanced technology and professional experience.

Our Misson

Our mission is to provide our customers with the best quality, performance and service of our products.

Advancing products, processes and solutions

The production of abrasives is a process of using natural or synthetic minerals to create various tools for cutting, grinding, polishing and finishing different materials. Abrasives are characterized by their hardness, shape, size and performance. Abrasives can provide solutions for various industrial, domestic and technological applications that require high precision, quality and efficiency.

The raw materials, such as bauxite, carbon material, and iron filings, are proportionately mixed together and sent to the electric arc furnace for smelting.

Smelting: The electric arc furnace melts the raw materials with a graphite electrode at a high temperature of over 2000°C for more than 20 hours, resulting in corundum

The corundum is cooled naturally for 24 hours and then water-cooled, forming high-quality corundum blocks

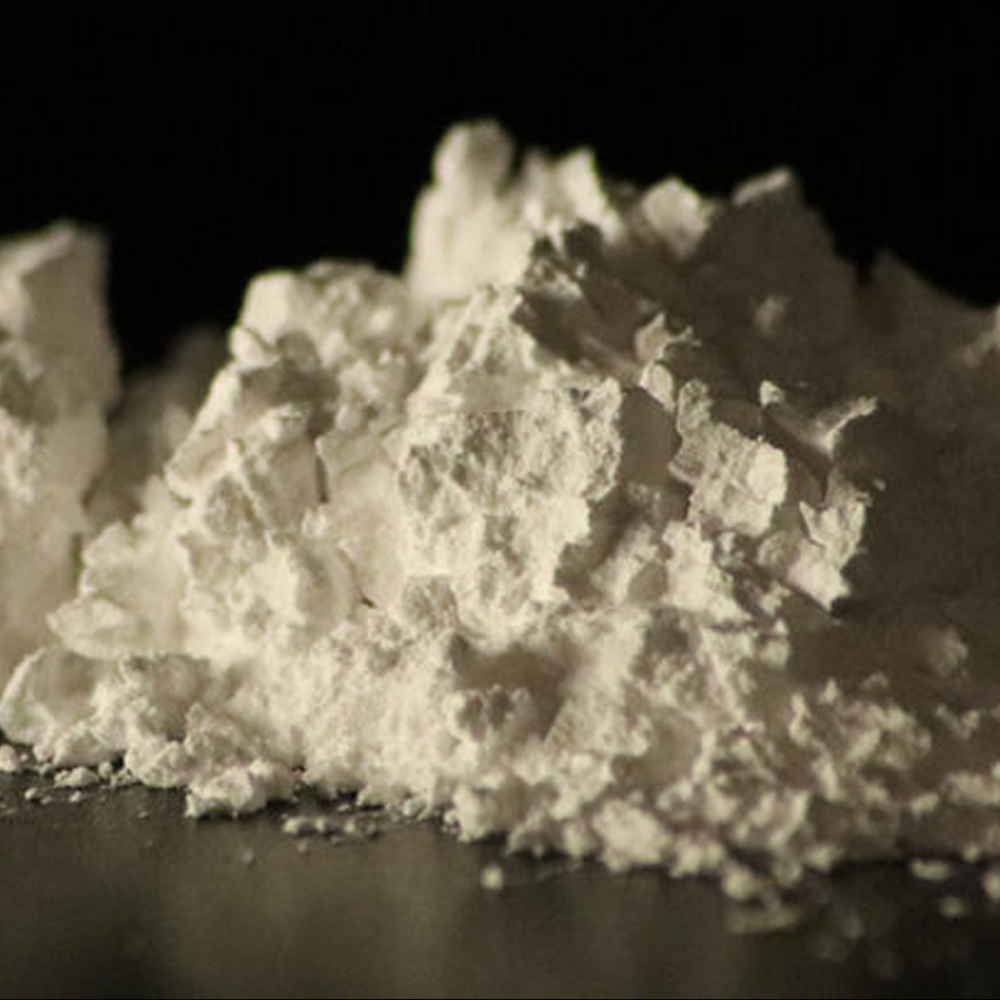

Crushing: The corundum blocks are crushed into various particle sizes of corundum sand with a crusher, a roller machine, a ball mill, or a Bamak production line

Magnetic separation: A high magnetic separator is used to remove impurities such as ferrosilicon from the corundum sand

A Raymond mill is used to make corundum powder

Sample testing: The corundum powder is tested in the laboratory for quality and performance

Abrasive solutions are the use of natural or synthetic minerals to create various tools for cutting, grinding, polishing and finishing different materials with high precision, quality and efficiency.Industrial abrasives typically consist of grains of a hard synthetic material, such as brown fused alumina.

Our not-so-secret plan: Create a world without waste

We are a factory that produces high-quality abrasive grains with advanced technology and professional experience.

Case Studies

We are proud to share some of the successful stories of how our abrasive products and solutions have helped our customers achieve their goals and improve their products.

Abrasive Technologies

Advanced automated production ensures quality that meets the highest international standards. Our manufacturing facilities include cutting-edge machinery from the world’s leading suppliers, automated testing and quality control, optimized warehouse logistics and expert staff committed to excellent service.

Recent News

Sintered vs Electrofused AZS Refractories: What’s the Key Differences

Sintered AZS Bricks Sintered AZS bricks are manufactured using zircon and alumina as the main raw materials, with pre-synthesized batches as aggregates. Since the non-plastic powders