Description

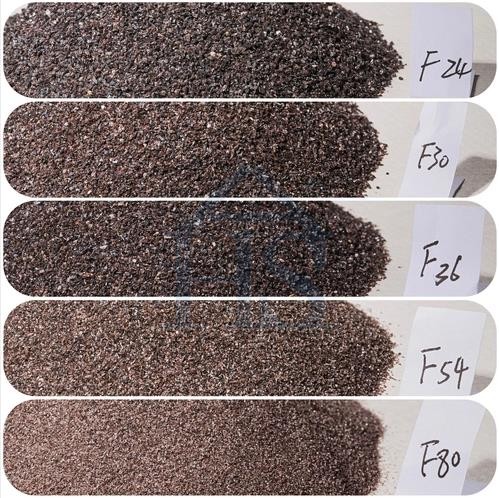

Brown Fused Alumina also known as electrocorundum, corundum, and aluminum oxide is fused and crystallized under the high temperature of above 2250°C in arc furnace with high quality abrasive bauxite as raw material. Brown fused aluminum oxide is a tough, hard material (Mohs hardness 9, ) with high strength, excellent wear and corrosion resistance and good thermal conductivity. Brown Fused Alumina can produce bonded abrasives, coated abrasives. A could be used for abrasive、sandblasting and precision casting and use as refractory materials.

High Hardness

Brown Fused Alumina has a Mohs hardness of 9, making it one of the hardest abrasives available in the market. This characteristic ensures that it can withstand the toughest applications and provide consistent results over time.

High Toughness

Brown Fused Alumina has excellent toughness, which allows it to resist fractures and breakage. This toughness also makes it suitable for high-pressure applications that require a strong abrasive.

High Density

Brown Fused Alumina has a high density, which ensures that it can cut through tough materials quickly and efficiently. This density also helps to reduce the amount of dust generated during the cutting process, making it a cleaner and safer abrasive to use.